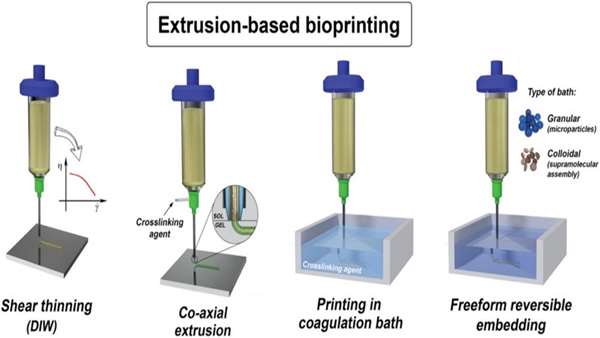

3D bioprinting has produced various types of tissue constructs, such as cardiac, vascular, muscle, and cartilage. Control over the organization of materials, cells, and biomolecules in the resulting 3D constructs are needed. Researchers have developed an extrusion strategy based on the use of coaxial extruders. Introducing GNRs (gelatin methacryloyl-coated gold nanorods) in the bioink not only facilitated the printability due to the shear-thinning effect, but also promoted cell to cell interactions.

Authors used 3D bioprinting of fibroblast-laden filaments to engineer a blood vessel-like structure. Printing speeds of 5 and 10 µL min−1 resulted in cell viability of over 70% when the UV light exposure was below 30 s. Authors suggested to use SMCs(smooth muscle cells) and ECs(endothelial cells) to engineer blood vessels in future. The ability to construct vascular channels on a large scale mimicking the native vasculatures is critical for the clinical application of any engineered tissue. The use of microfluidic-based 3D bioprinting is expected to enable the development of a broad range of functional tissues with many important applications in basic research, drug discovery, product testing, and ultimately in the clinic. Conceptually, it broadly expands the design space and ultimately tissue complexity as it enables us to have greater control over deposited bioinks and resulting structures. There have already been many reported examples of direct application of this technology to biofabrication of functional cell-laden fibers through wet spinning and recently 3D printed and viable tissue constructs.

ارسال به دوستان